- Home

- Products

- Compound Granules

- Modified PMMA Resin

Modified PMMA Resin

Qingdao Zhongxinhua Mei Plastic Co., Ltd. is a professional manufacturer of engineering plastic materials. You can order high-quality polyamide 6, paraformaldehyde, polycarbonate, polybutylene terephthalate and acrylonitrile butadiene styrene at favorable prices directly from our factory.

- Compound Granules

- Plastic raw materials

- PCR Granule

Toughened Acrylic (Impact Modified PMMA)

Top Advantages: High Impact: Significantly higher break resistance than standard PMMA.

Crystal Clear: Maintains excellent light transmission (up to 92%).

Weather Proof: Outstanding UV resistance for outdoor durability.

Easy Processing: Optimized flow for complex injection molding.

Custom Color: Clear or custom tints available (RAL/Pantone).

Main Applications:

Automotive: Tail light covers, instrument panels, and trim.

Electronics: Screen protectors, display panels, and lenses.

Household: High-end cosmetics packaging and appliances.

Compliance: UL-94, RoHS, REACH, ISO9001.

Contact Us: Email: info@qdzxhm.com.cn Free Samples & TDS Available.

Toughened acrylic (Impact Modified PMMA) is an advanced optical-grade polymer engineered to bridge the gap between high transparency and mechanical durability. By incorporating specialized impact modifiers into the acrylic matrix, our toughened acrylic delivers the iconic clarity of glass with the robust shatter resistance required for demanding industrial and consumer applications.

| Physical properties table Flame retardant,heat resistant,impact resistant18 properties one-stop customization | ||||

| AVERAGE GRADE | ||||

| ITEM | UNIT | CM-205 | CM-207 | CM-211 |

| Tensile Strength | MPa | 68 | 64 | 60 |

| Elongation at break | % | 10 | 7 | 7 |

| Bending elasticity | GPa | 3.2 | 3.2 | 3.2 |

| Flexural Strength | MPa | 110 | 94 | 90 |

| Rockwell strength | ASTM | M-95 | M-88 | M-84 |

| IZOD impact strength | KJ/m² | 1.8 | 1.7 | 1.6 |

| Total light transmittance | % | 92 | 92 | 92 |

| Softening point | °C | 115 | 108 | 103 |

| Heat distortion temperature | °C | 95 | 90 | 87 |

| Density | g/cm³ | 1.19 | 1.19 | 1.19 |

| Melt Flow Rate | 230°C*3.8kg cm³/10min | 2 | 9 | 17 |

| Combustion rate | UL | 1.5mmHB | 1.5mmHB | 1.5mmHB |

| Product Characteristics | / | High strength injection moldable and extrudable | medium intensity | high mobility |

Key Technical Advantages of Toughened Acrylic

Exceptional Impact Strength: Toughened acrylic is specifically formulated to absorb energy and resist cracking, making it several times stronger than standard PMMA under physical stress.

Superior Optical Clarity: Despite the toughening modification, our toughened acrylic maintains a light transmission rate of up to 92%, ensuring zero distortion for lenses and displays.

Excellent Weatherability: Toughened acrylic possesses inherent UV stability, preventing yellowing or degradation even after long-term exposure to direct sunlight.

Enhanced Chemical Resistance: Our toughened acrylic grade offers improved resistance to common household chemicals and oils compared to general-purpose acrylics

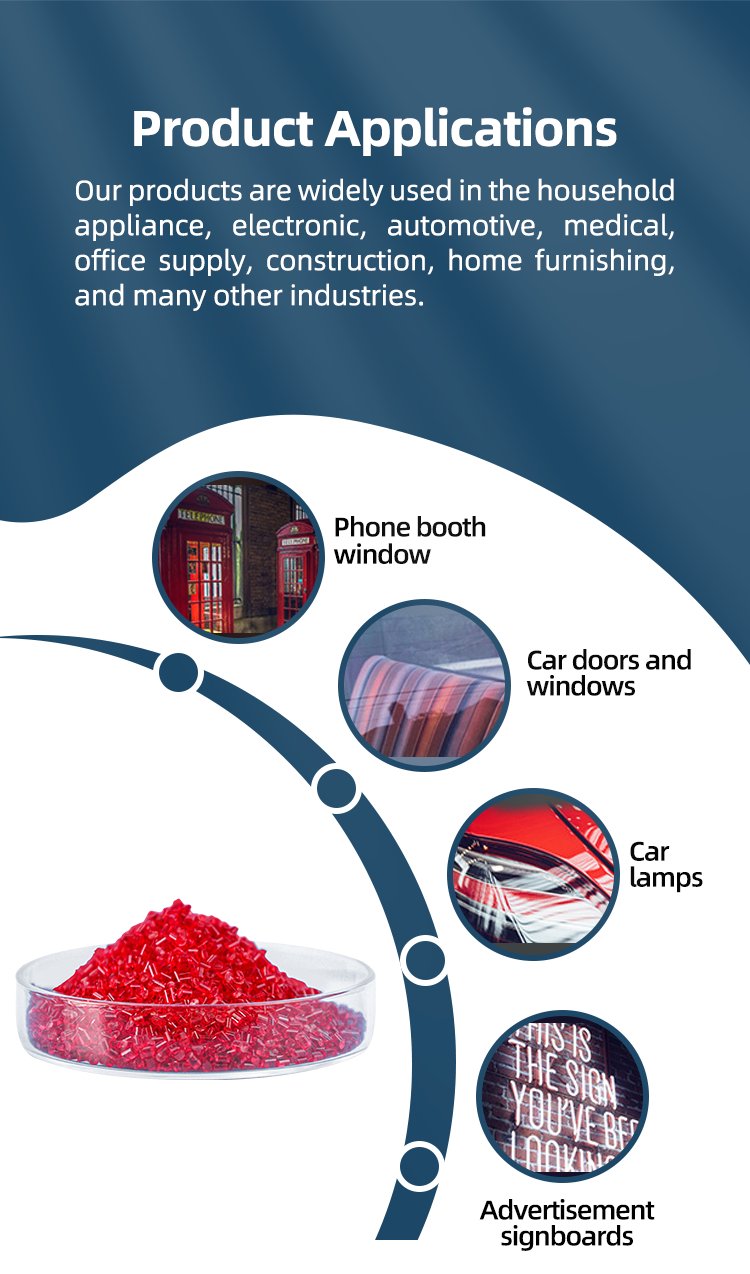

Typical Applications of Toughened Acrylic

Automotive Industry: Used for toughened acrylic taillight lenses, decorative pillars, and dashboard covers where safety and aesthetics are paramount.

Optical & Display: The preferred material for toughened acrylic smartphone screens, monitor panels, and high-precision optical lenses.

Industrial & Lighting: Ideal for protective covers, street lamp housings, and illuminated signage that require long-term outdoor reliability.

Equest a Quote for Toughened Acrylic

As a direct manufacturer of specialty materials like toughened acrylic, we cut out middlemen to offer you discounted pricing. Discover more details about our impact modified solutions and request free samples—click here!Email: info@qdzxhm.com.cn

√ Client:Premier Spanish automotive injection molding manufacturer

√ Position:Core supplier to international Tier-1 automotive OEMs (BMW, Volkswagen, etc.)

√ Application:Automotive parts production

√ Material type:PP+EPDM+TD、 glass fiber reinforced PP

√ Critical Performance Metrics:Color consistency guaranteed at ΔE < 0.2、Batch-to-batch performance stability